Products

- Self-cleaning filter

- Automatic backwash filter

- Candle type filter

- Metal Sintered Backwash Filter

- Scraper Filter

- Bag filter

- Tubular type backwash filter

- Media Filter

- Cartridge Filter

- Large flow cartridge filter

- Gas Filtration and Purification

- Natural Gas Filtration and Separation

- Static mixer serial

- Filter element

Contact Us

-

0510-82621388

0510-82621388

-

0510-83782353

0510-83782353

-

No. 15, Furong Industrial Park, Xishan Economic Technology Development Zone, Wuxi

No. 15, Furong Industrial Park, Xishan Economic Technology Development Zone, Wuxi

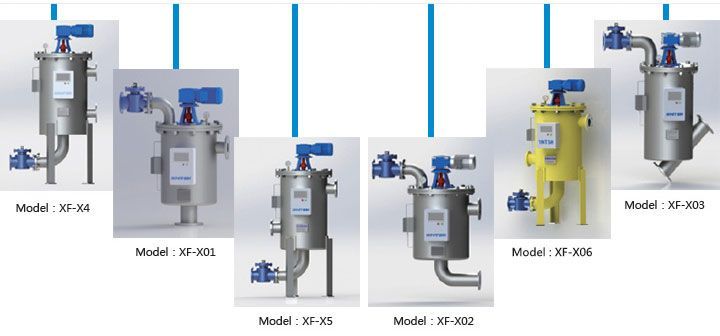

INOCO-XF-X model automatic self cleaning filter is a kind of filter suitable for bad environment, it can be equipped with 3500 microns - 50 micron mesh and 8-36 "pipeline diameter for different using requirements. The cleaning process is started by a differential pressure switch which is monitoring the different pressure of inlet and outlet , usually the default value of pressure difference switch is 0.5 bar (7 psi). XF-X series self cleaning filter is suitable for filters with 1"~ 36" pipeline to choose from. With advantages of continuously fluid flow, safety operation, simple maintenance , XF-X series self cleaning filter is widely used in all industries area.

- Product Overview

- Drawings and Data

- applied Range

- Product Configuration

When the differential pressure of inlet and outlet reaches the preset value, the filter will start the cleaning process. The whole self-cleaning process contains two steps: the drain valve on the end cover of the filter opens; the two stainless steel brushes in ontology mesh is driven by motor inside, then the impurities which is captured by mesh will be brushed by the steel brush and will be discharged from the drain valve. The whole cleaning process takes about 15 to 60 seconds, During this time, the filtration system does not stop and the whole operation process is completed by a control box.。

General parameters

Operation flow rate : 20-5000m3/h

Different water quality filter precision have different flow rate contact with supplier for the detail;

Min working pressure : 2bar;

If the working pressure is low, then booster pump equipment can be set in the drain outlet;

Max working pressure : 10bar ; 150psi;

According to users' requirements, high pressure filters can be made, please contact manufacturer for details;

Filtering area : 3000cm2 -20000 cm2;

Inlet/outlet diameter : 50,80,100,150,200,250,300,350,400,500,600,800mm;

Max working temperature : 50°C;

Special Notes:please notify if the temperature is above this temperature.

Cleaning parameters

Drain valve Size:25mm; 50mm; 80mm;

Cleaning time:30-60S;

Cleaning water consumption (every time) :≤1%

Filter body - cap

Filter body : Carbon steel ,Epoxy resin coating; stainless steel 316、304 can be choose according to requirement;

Filter mesh : Stainless steel 316L Wedge cartridge ; Stainless steel 316L woven wire cartridge

Clean body (interior) : Stainless steel 304,316L, POM;

Drain valve : Cast iron, epoxy resin coating; 304,316L;

Seal ring : synthetic rubber, PTFE.

Control - power distribution

Control voltage : 24V or choose 10V or 24V per requirement;

Motor power : 0.35-1.0, 50Hz;

Rated operating voltage : 3 phase, 220/380V(according to requirement);

Electricity : 1.5-2A.

Standard filter rating

Woven type mesh accuracy:500, 300, 200, 130, 100, 80, 50, 25, 10 micron;

Wedge cartridge accuracy:50,80,100, 200, 300, 500 micron.

Filter body - cap

Filter body : Carbon steel ,Epoxy resin coating; stainless steel 316、304 can be choose according to requirement;

Filter mesh : Stainless steel 316L Wedge cartridge ; Stainless steel 316L woven wire cartridge

Clean body (interior) : Stainless steel 304,316L, POM;

Drain valve : Cast iron, epoxy resin coating; 304,316L;

Seal ring : synthetic rubber, PTFE.

INOCO XF-X Brush self cleaning Filter data sheet

|

Model No.

|

X01

-219 |

X01

-273 |

X01

-325 |

X01

-426 |

X01

-530 |

X01

-630 |

X01

-720 |

X01

-820 |

X01

-920 |

X01

-1020 |

|

Pipe diameter (mm)

|

50

|

80

|

100

|

200

|

250

|

300

|

350

|

400

|

450

|

500

|

|

Filter flow rate (m3h)

|

20

|

50

|

150

|

300

|

500

|

700

|

1100

|

1500

|

2000

|

2500

|

|

Filtration area (m2)

|

0.27

|

0.25

|

0.35

|

0.66

|

1.6

|

0.85

|

1.3

|

1.4

|

1.8

|

2.3

|

|

Drain valve DN (mm)

|

25

|

25

|

25

|

50

|

50

|

80

|

80

|

80

|

80

|

80

|

|

Clean water consumption per once(L)

|

80

|

80

|

80

|

150

|

150

|

350

|

450

|

600

|

800

|

1000

|

|

Motor power (KW)

|

0.55

|

0.55

|

0.55

|

0.55

|

0.55

|

0.75

|

0.75

|

0.75

|

0.75

|

0.75

|

|

Model No.

|

D(mm)

|

H(mm)

|

H1(mm)

|

H2(mm)

|

L1(mm)

|

L2(mm)

|

|

X01-219

|

219

|

450

|

830

|

1130

|

/

|

190

|

|

X01-273

|

273

|

500

|

885

|

1185

|

/

|

217

|

|

X01-325

|

325

|

500

|

945

|

1170

|

/

|

283

|

|

X01-426

|

426

|

500

|

1130

|

1350

|

325

|

343

|

|

X01-530

|

530

|

650

|

1330

|

1550

|

370

|

415

|

|

X01-630

|

630

|

685

|

1360

|

1660

|

400

|

460

|

|

X01-720

|

720

|

700

|

1500

|

1730

|

400

|

510

|

|

X01-820

|

820

|

765

|

1600

|

1870

|

450

|

600

|

|

X01-920

|

920

|

900

|

1720

|

1980

|

450

|

660

|

|

X01-1020

|

1020

|

920

|

1850

|

2100

|

500

|

710

|

|

Application field of wedge filter

Water - sewage |

Wedge element advantages:

Surface is not easy to plug |

If there is any relevant liquid / solid separation in the actual project, we could supply high quality, various products and senior filtration engineers to help you maximize your benefits and benefits.

Products configuration