Products

- Self-cleaning filter

- Automatic backwash filter

- Candle type filter

- Metal Sintered Backwash Filter

- Scraper Filter

- Bag filter

- Tubular type backwash filter

- Media Filter

- Cartridge Filter

- Large flow cartridge filter

- Gas Filtration and Purification

- Natural Gas Filtration and Separation

- Static mixer serial

- Filter element

Contact Us

-

0510-82621388

0510-82621388

-

0510-83782353

0510-83782353

-

No. 15, Furong Industrial Park, Xishan Economic Technology Development Zone, Wuxi

No. 15, Furong Industrial Park, Xishan Economic Technology Development Zone, Wuxi

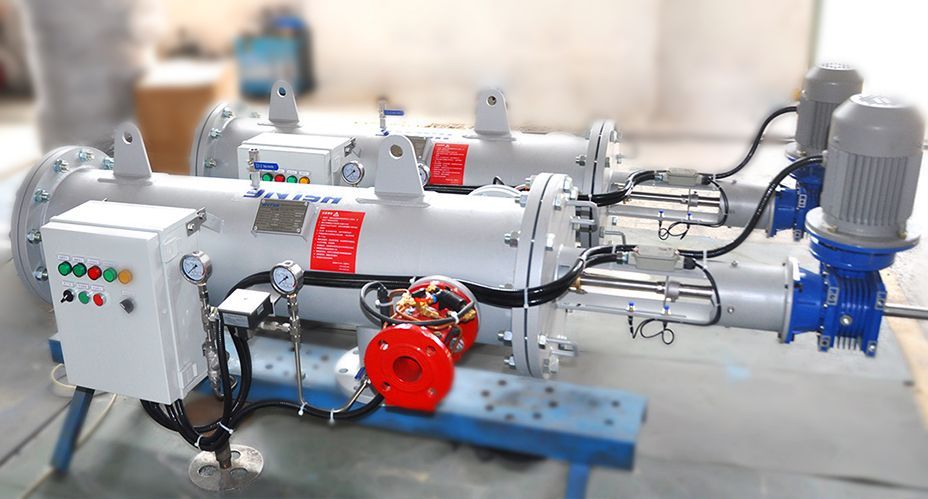

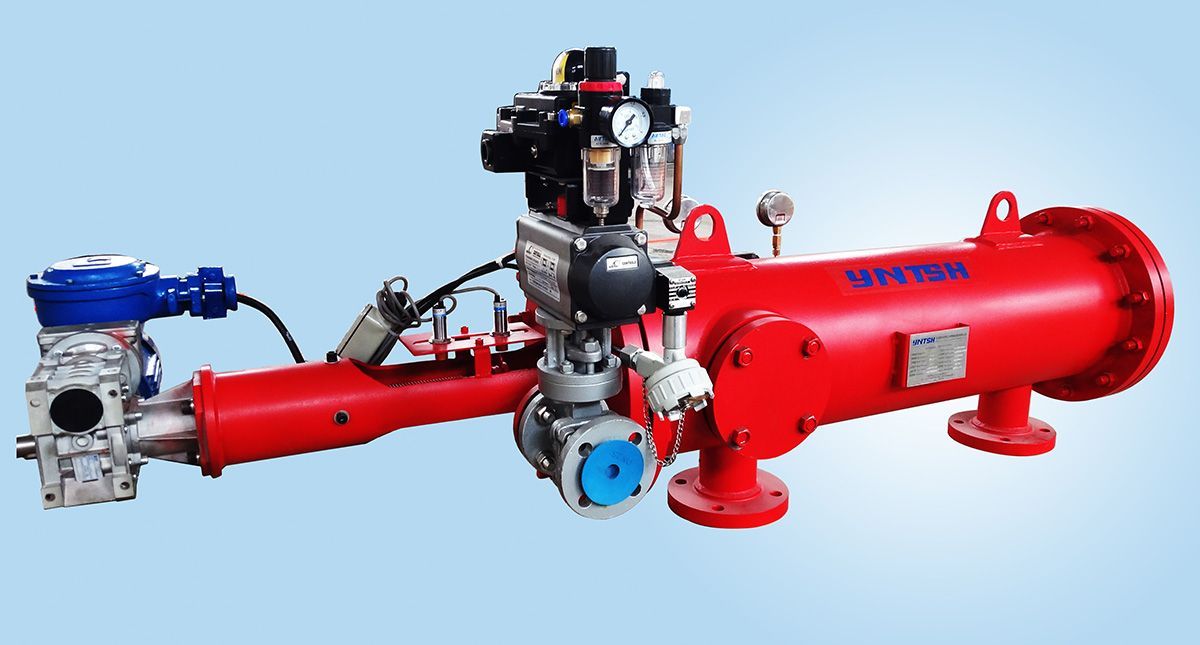

XF - D2 series self cleaning filter has higher filtration precision and minimum cleaning water loss, it can provide the most security for industrial system.

- Product Overview

- Drawings and Data

- applied Range

- Product Configuration

When the pressure difference inside - outside of filter mesh reaches the set default value or when the timing cleaning switch reaches the set time, then system starts the cleaning process.

The cleaning process is done by a sucking scanner, it makes a spiral scanning movement and absorbs the impurity on the surface of the mesh and discharges through a drain valve, the scanner is driven by a two-way rotation of the electric motor through a screw.

The opening of drain valve is controlled by a two position three-way solenoid valve, the whole process lasts about 35 seconds, in this process system keeps continuously flow.

Filter performance

Continuous water supply: the cleaning process needs little water, which is nearly 1% of filter water yield, the flushing time is 15 ~ 60 seconds, the whole system uninterrupted water supply.

High filtration precision: the filtering precision can reach 20 microns, there are all kinds of precision filters can be chosen.

Large filtering area: the effective filtering area of standard mesh is 7 ~ 40 times of the inlet area.

Fast and efficient cleaning technology of continuously flow after filtration

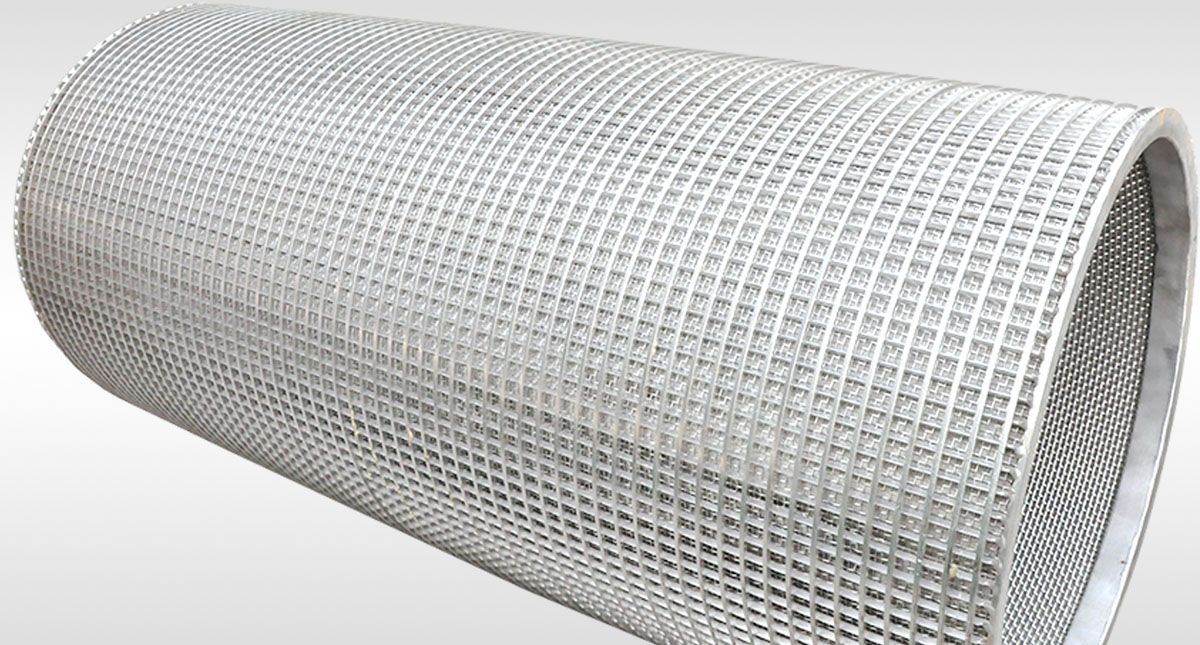

Sucking scanning filter contains a unique multi-layers stainless steel meshes, the filtration precision can reach up to 10 microns; Inoco design team developed a most effective method to combine material strength, filtering capacity and cleaning efficiency effectively togetherby by selecting mesh weaving method and structure mode, in order to achieve a more efficient filtering results. This cutting-edge precision filter mesh ensures the filter cake can be cleaned quickly and thoroughly. The water consumption of Inoco sucking scanning technology is less than 1% of the total water which is the lowest emissions of all water rate among all self-cleaning mode.(the rate could be adjusted according to the specific application)

filter housing - cover

Filter body: Carbon steel 20# Epoxy resin coating;stainless steel 316;

End cap: SMC Polyester

Filter mesh: Stainless steel 316L woven mesh,Stainless steel 316L

Clean body (interior): Stainless steel316L, POM

Drain valve: Cast iron, epoxy resin coating; 304,316L

Seal ring: synthetic rubber, PTFE

Work flow

Water is flowing through filter inlet and flows from outside to inside toward coarse mesh then flows through fine mesh out from inside to outside ,the impurity will be intercepted by the fine mesh in this process and also forming some pressure loss ,Coarse mesh is designed to protect the clean equipment and avoid big particles from damaging so that it is not for filtration.

INOCO XF-D2 series self cleaning filter comprehensive parameters

|

Model

|

Flow rate

|

Accuracy(μm)

|

Filtration area(C㎡)

|

H(mm)

|

L(mm)

|

|

XF-D2-50

|

80

|

100

|

1500

|

1800

|

430

|

|

XF-D2-80

|

150

|

100

|

3000

|

2050

|

430

|

|

XF-D2-100

|

250

|

100

|

4500

|

2350

|

525

|

|

XF-D2-150

|

400

|

100

|

6000

|

2100

|

595

|