Products

- Self-cleaning filter

- Automatic backwash filter

- Candle type filter

- Metal Sintered Backwash Filter

- Scraper Filter

- Bag filter

- Tubular type backwash filter

- Media Filter

- Cartridge Filter

- Large flow cartridge filter

- Gas Filtration and Purification

- Natural Gas Filtration and Separation

- Static mixer serial

- Filter element

Contact Us

-

0510-82621388

0510-82621388

-

0510-83782353

0510-83782353

-

No. 15, Furong Industrial Park, Xishan Economic Technology Development Zone, Wuxi

No. 15, Furong Industrial Park, Xishan Economic Technology Development Zone, Wuxi

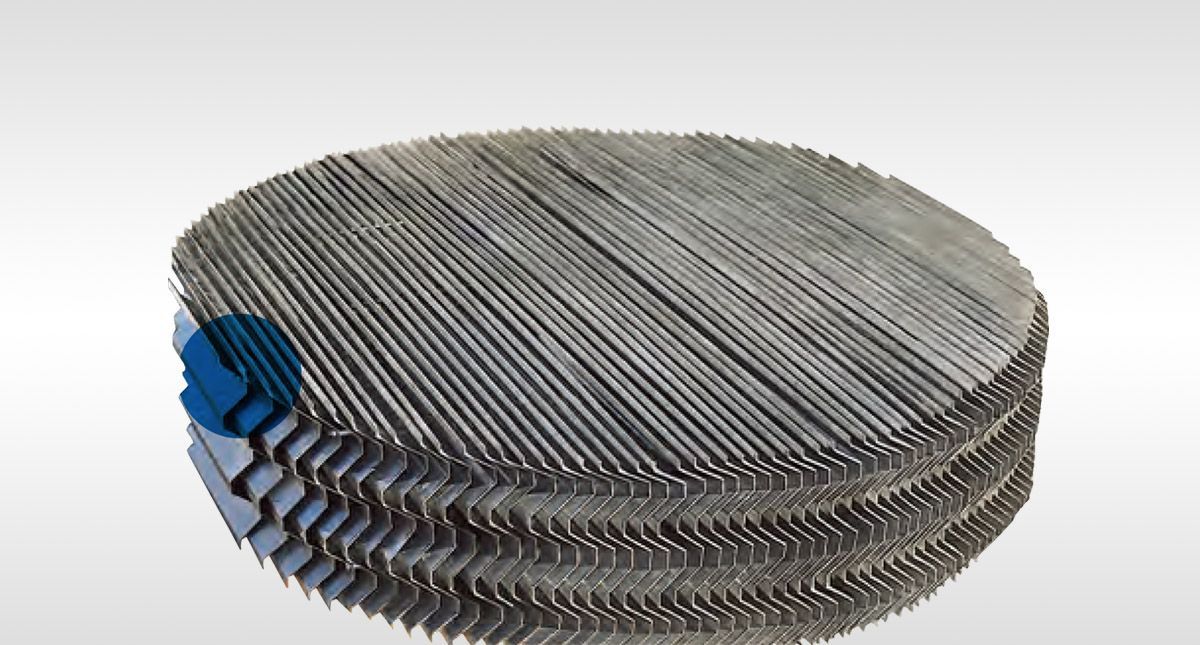

INOCO Series 700 Separating filter is combined by YNT vane separated and YNT coalescence elements. the droplets more than 5-8μm can be 100% separated and the solid particles 0.5μm are 99% filtered.

- Product Overview

- Drawings and Data

- applied Range

- Product Configuration

Vane separator can treat various ratio of gas-liquid medium. It is having high efficiency to solve large amounts of liquid.

The vane element can be fixed or movable structure

Welded or bolted bracket

Available to add the self-cleaning system

Available to increase the variety of flow distribution structure

Recovery (methyl alcohol, hydrogen nitride)

transport pipelines, main dispatch station, gas gathering system

The compressor entrance dispenser

Fuel gas scrubber, The combustion exhaust gas scrubber

Pulp mill evaporator

1. Gas and fine mist are forced to change direction many times in passing through vane array

2. Larger droplets keeps straighter Movement so as to easy seperation

3. Captured droplets merge until heavy enough to fall.

Working principle Three steps of separating process for cartridge vane filter separator:

Step 1: Gravity separating

Gas flows into the filter body from inlet pipe. With the strong impact towards the shell surface or cartridge frame, impurity substances in big size will be separated;

Step 2: Screening holes separating

Rechargeable filtering devices are equipped at the head side of the separator. The type and accuracy level can be chosen with different working requirements. Solid impurity substances in minimal size will be gathered into mist style stuff and removed.

Step 3 Leaf separating

Leaf separator is used to remove liquid impurity substance which will be gathered in a proper container inside.