Products

- Self-cleaning filter

- Automatic backwash filter

- Candle type filter

- Metal Sintered Backwash Filter

- Scraper Filter

- Bag filter

- Tubular type backwash filter

- Media Filter

- Cartridge Filter

- Large flow cartridge filter

- Gas Filtration and Purification

- Natural Gas Filtration and Separation

- Static mixer serial

- Filter element

Contact Us

-

0510-82621388

0510-82621388

-

0510-83782353

0510-83782353

-

No. 15, Furong Industrial Park, Xishan Economic Technology Development Zone, Wuxi

No. 15, Furong Industrial Park, Xishan Economic Technology Development Zone, Wuxi

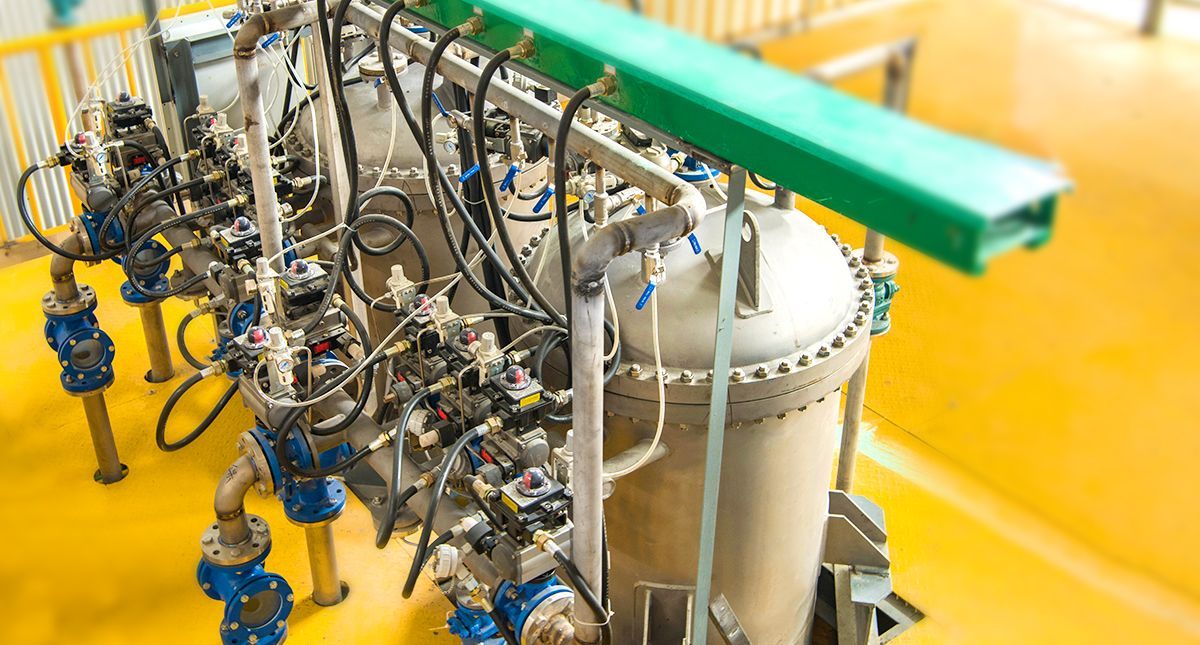

INOCO-DS-A7 type candle filter , can be automatically regenerated without stopping the system. It is a kind of automatic self-cleaning filter, which can effectively eliminate manual cleaning ,no need to replace the filter element. It is widely used in the continuous production, high-risk operating environment and the application where is not suitable for metal filter element. INOCO DS-BG series candle filter is a new type of filter system, which can be designed and manufactured according to GMP standard.The advantage of the filter is that it can complete the function of filtering, washing and discharging slag in the shell.

- Product Overview

- Drawings and Data

- applied Range

- Product Configuration

INOCO DS-BG series tubular automatic backwash filter

INOCO-DS-A7 type candle filter , can be automatically regenerated without stopping the system. It is a kind of automatic self-cleaning filter, which can effectively eliminate manual cleaning ,no need to replace the filter element. It is widely used in the continuous production, high-risk operating environment and the application where is not suitable for metal filter element

Working principle

During filtration , The material liquid with catalyst enters from the outside of the filter and passes through the filter internal part from the outside to the inside. Impurities larger than the filter hole are knocked down and accumulated on the surface and material will form filter cake, By bridging, the filter cake can catch some finer impurities in the water. When the impurities accumulate to a certain extent, the pressure difference rises to the set value of the system, the inlet and outlet fluid valve is closed, the compressed gas enters and dries the filter cake, in the backwashing processing , the particles will be removed, and the filter element could be regenerate .

DS-BG-2 series thickening unit

The pre-filtration step is followed by a longer or shorter filtration step.This step terminates with the stop of the feed,discharge is accomplished by backblowing, but it is not necessary to empty the liquid in the filter. This step makes the filter cake fall off and sink to the cone of the filter within a few seconds after backblowing, and then the filtration cycle returns to normal. The thick slurry after thickening is discharged from the machine by opening the discharge valve in the next filtration cycle and has no influence on the filtration step.

Filter feature

Wet and dry discharge,the solids are dehydrated and discharged by the back blowing of the gas, which can also be used for the rereaction of the filter cake.

Continuous thickening

The filter continuous filtration is allowed. Solids are flushed back into the liquid and discharged as slurry. Suitable for processes requiring continuous filtration.

Sanitary filter

This filter is designed to meet the high production standards of pharmaceutical, fine chemicals. All surfaces and components in contact with the product that allow for efficient cleaning.

Back blow

Whether dry or wet discharge, discharge is achieved by internal everse pressure into the filter rod. The unique structure is more conducive to reverse blowing: the rapid outward expansion of the filter cloth during reverse blowing, especially in the area where the filter cake is attached, leads to the vertical cracking of the filter cake. An instant blowback air (such as air or nitrogen) within the cloth causes the cracked cake to be thrown away from the cloth.

The filtration system has been successfully applied in many fields and can be used in the production of the following products :

Titanium dioxide/current board /Viscose fiber/Nickel production/Flue gas desulfurization/Wastewater treatment/Resin/Production of PVC/Removal pf catalyst/Phosphating/Activated carbon/Zeolite production/Production of edible oil/Chlor alkali production/Polyol/Gas desulfurization

-

No Prev

-

No Next