Products

- Self-cleaning filter

- Automatic backwash filter

- Candle type filter

- Metal Sintered Backwash Filter

- Scraper Filter

- Bag filter

- Tubular type backwash filter

- Media Filter

- Cartridge Filter

- Large flow cartridge filter

- Gas Filtration and Purification

- Natural Gas Filtration and Separation

- Static mixer serial

- Filter element

Contact Us

-

0510-82621388

0510-82621388

-

0510-83782353

0510-83782353

-

No. 15, Furong Industrial Park, Xishan Economic Technology Development Zone, Wuxi

No. 15, Furong Industrial Park, Xishan Economic Technology Development Zone, Wuxi

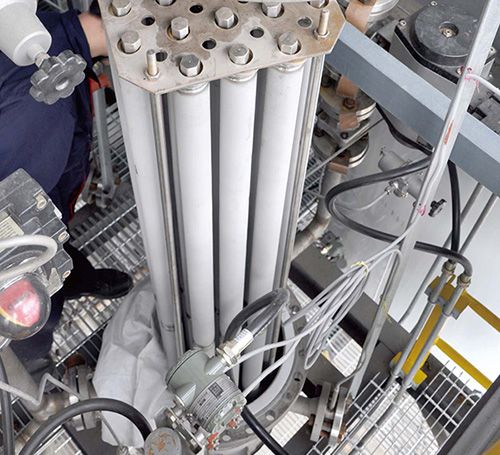

Since its establishment, INOCO has sold nearly 10,000 microporous metal filters and hundreds of thousands of sintered filter elements;The core filtration medium of the microporous metal filter adopts the metal powder unsintered filter core developed by INOCO's fourth-generation technology, and the filtration accuracy can reach 0.5μm to 5μm, which is suitable for various complex working conditions。

- Product Overview

- Drawings and Data

- applied Range

- Product Configuration

INOCO DS-G1 series metal powder backwash filter is suitable for filtering materials with high solid content ,high tempreture and high presure.The filter adopts three cleaning methods of back flow, blasting, ultrasonic which can be operated automatically continuously and avoid frequent manual cleaning and unnecessary stopping.and max reduce environment pollution from filter materials and residue .

INOCO DS-G1 series metal sintered backwash filter advantage

1.Little residual liquid:

According to the nearly ten years of experience, combining with the core filter elements and cleaning procedures, the cleaning effect is equivalent to more than 80% of the initial state, which greatly extends the service cycle of the filter and reduces the amount of pollutant emission by 72%.

2.Excellent filter element, metal powder sintered filter element, no need to change the filter element frequently

INOCO fiter uses a unique process to sinter stainless steel powder with high strength and open rate, filtration rating can be upto 1micron/99% .

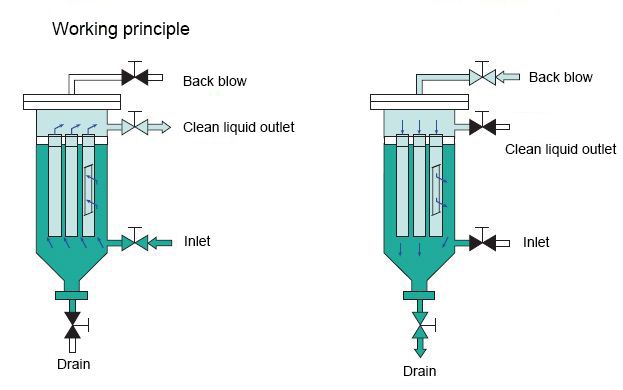

3.Fully closed structure, 100% automatic, suitable for all kinds of complicated and explosion-proof occasions.

INOCO microporous filter is equipped with a variety of pneumatic or electric valves to achieve automatic filtration and cleaning process and reduce manual cleaning and improve production efficiency.

4.Matured system solutions

INOCO porous metal sintered filter has a lot of successful solutions, flow rate can be 1-200t/h. Mostly own mature drawing to choose .

5.Wide range of filter element sizes and materials

INOCO can provide powder sintered filter elements from 10mm to 200mm in diameter, and the material includes 304L, 316L, Monel ,nickel base alloy.

Filter parameter

|

Shell materil

|

Carbon steel

|

304、321、316L、2507

|

Incoloy、C276 etc .

|

|

Design pressure

|

0.1~5.0Mpa

|

0.1~5.0Mpa

|

0.1~5.0Mpa

|

|

Design tempreture

|

-196~400℃

|

-196~500

|

-196~1000℃

|

|

Filtration rating(liqiud)

|

1~10μm

|

1~10μm

|

1~10μm

|

|

Clean way

|

Manual or automatic

|

||

Design of Backwash Filter

INOCO has the leading filtration laboratory in China, such as laser particle size tester, integrity tester, etc. Our backwash filter has a small test ,pilo test , so that we can guarantee to provide the most reliable design for yourcondition.We also know that customers develop new products is a demanding and expensive work , so our professional team provide fast and effective filtering solution for every stage .

DS-G1 Metal menbrane backwash filter , it is universal type filter, suitable for most working conditions.Filtration way: from outside to inside .

Working principle

Catalyst

Recovery of precious metals and metal catalysts

Oil slurry filtration in catalytic cracking unit

PTA PRODUCTION CTA,PTA and catalyst recovery system

Coal to olefins (MTO) catalyst recovery system

Catalyst and regenerator exhaust gas purification system

Hydrogenation of raw oil ,circulating oil filtration system

Aviation fuel oil,coke distillates filtration system

Fine Chemical

Fluidized bed hydrogenation process for hydrogen peroxide production

Oily sludge treatment system

Fiber spinning

Armatic spieces

Coal chemical

Coal gasification filtration system, coal gasification to ethylene glycol, etc

Food, beverage, water treatment

FGD wastewater treatment

Washed water,injection olution, beverage filtration and clarification

Gas filtration and purification

Silicon powder conveying process exhaust filtration

Filtration of trichlorosilane syngas

Trichlorosilane end gas filtration

Silicon tetrachloride end gas filtration

Burning end gas filtration

SHELL gasification tempreture gas filtration

High temperature gas filtration in olefin unit

Instrument medical gas protection

Gas protection for new coal chemical and medical gas

New coal chemical gas filtration

-

No Prev

-

No Next