Products

- Self-cleaning filter

- Automatic backwash filter

- Candle type filter

- Metal Sintered Backwash Filter

- Scraper Filter

- Bag filter

- Tubular type backwash filter

- Media Filter

- Cartridge Filter

- Large flow cartridge filter

- Gas Filtration and Purification

- Natural Gas Filtration and Separation

- Static mixer serial

- Filter element

Contact Us

-

0510-82621388

0510-82621388

-

0510-83782353

0510-83782353

-

No. 15, Furong Industrial Park, Xishan Economic Technology Development Zone, Wuxi

No. 15, Furong Industrial Park, Xishan Economic Technology Development Zone, Wuxi

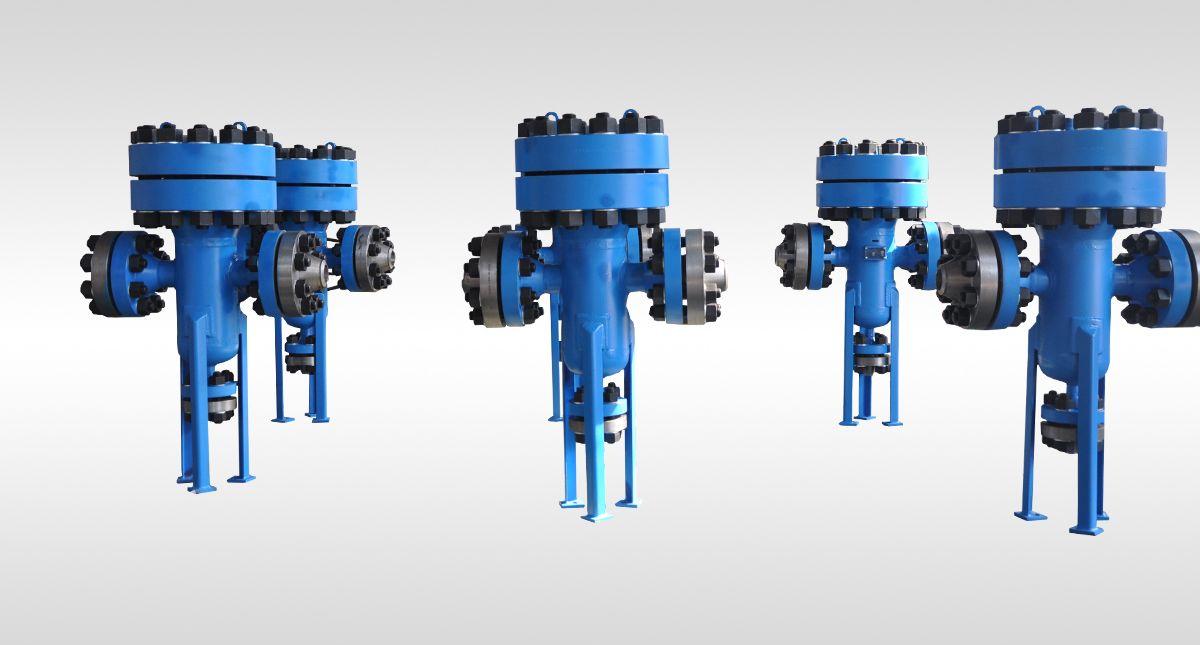

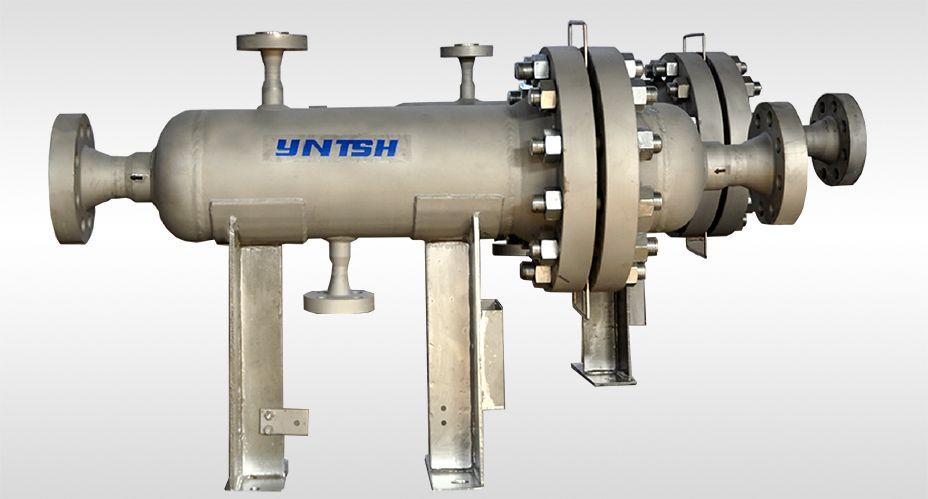

The working pressure range of INOCO SGA-D series high pressure filter is 25-400 bar, and it obtained the record of security and reliability within the scope. Compared with other products in filter industry, D series high pressure filter provides considerable technical and economic advantages for high pressure operation system.

- Product Overview

- Drawings and Data

- applied Range

- Product Configuration

Material

Top shell: CS(optional 16 MnR III), SS(316 III)

Bottom shell: CS(optional 16 MnR III),SS(316 III)

Sealing: fluorine rubber

Connection: flange, thread, butt welding

Filter element

Polyester filter element

glass fiber filter element

Washable Stainless steel filter element

Filtration precision: 0.003 micron to 10 micron

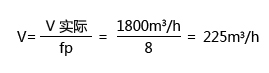

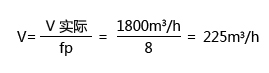

Eg: Gas flow rate is 360m3/h,

working pressure is 64bar, oil removal precision is 0.03mg/m3

|

Working pressure bar

|

7

|

25

|

40

|

64

|

100

|

250

|

400

|

|

Pressure correction coefficient

|

1

|

3

|

5

|

8

|

12

|

12

|

12

|

Eg: Gas flow rate is 360m3/h,

working pressure is 64bar, oil removal precision is 0.03mg/m3

|

Working pressure bar |

7

|

25

|

40

|

64

|

100

|

250

|

400

|

|

Pressure correction coefficient |

1

|

3

|

5

|

8

|

12

|

12

|

12

|

|

Filter model |

Max flow rate m3/minat 7bar |

Max working pressure |

Installation specification mm |

weight kg |

Filter element type |

Elements Qty. |

|||||||

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

H

|

||||||

|

SGD-D-30

|

30

|

64

|

165

|

85

|

R1/4”

|

145

|

130

|

90

|

50

|

4 XM8

|

1.6

|

03/05

|

1

|

|

D-60

|

60

|

64

|

165

|

85

|

R3/8”

|

145

|

130

|

90

|

50

|

4 XM8

|

1.6

|

03/10

|

1

|

|

D-120

|

120

|

64

|

205

|

105

|

R1/2”

|

185

|

190

|

110

|

50

|

4 XM8

|

2.6

|

04/20

|

1

|

|

D-180

|

180

|

64

|

230

|

105

|

R3/4”

|

205

|

190

|

110

|

50

|

4 XM8

|

2.8

|

05/20

|

1

|

|

D-270

|

270

|

64

|

235

|

119

|

R1”

|

210

|

190

|

130

|

70

|

4 XM10

|

4.3

|

05/25

|

1

|

|

D-360

|

360

|

64

|

290

|

119

|

R 1 1/4”

|

255

|

250

|

130

|

70

|

4 XM10

|

4.6

|

07/25

|

1

|

|

D-480

|

480

|

64

|

315

|

150

|

R 1 1/2”

|

280

|

250

|

160

|

80

|

4 XM10

|

7.4

|

07/30

|

1

|

|

D-720

|

720

|

64

|

405

|

186

|

R 2”

|

365

|

340

|

200

|

110

|

4 XM12

|

18.9

|

10/30

|

1

|

|

SGD-D2-30

|

30

|

400

|

170

|

85

|

R1/4”

|

150

|

130

|

90

|

50

|

4 X M8

|

5

|

03/05

|

1

|

|

D2-60

|

60

|

400

|

170

|

85

|

R3/8”

|

150

|

130

|

90

|

50

|

4 X M8

|

5

|

03/10

|

1

|

|

D2-120

|

120

|

400

|

210

|

105

|

R1/2”

|

190

|

190

|

110

|

50

|

4 X M8

|

9

|

04/20

|

1

|

|

D2-180

|

180

|

400

|

235

|

105

|

R3/4”

|

215

|

190

|

110

|

50

|

4 X M8

|

9.5

|

05/20

|

1

|

|

D2-270

|

270

|

400

|

250

|

119

|

R1”

|

220

|

190

|

130

|

70

|

4 X M10

|

14.5

|

05/25

|

1

|

|

D2-360

|

360

|

400

|

305

|

119

|

R 1 1/4”

|

270

|

250

|

130

|

70

|

4 X M10

|

16

|

07/25

|

1

|

|

D2-480

|

480

|

400

|

330

|

150

|

R 1 1/2”

|

295

|

250

|

160

|

80

|

4 X M10

|

27.5

|

07/30

|

1

|

|

D2-720

|

720

|

400

|

420

|

186

|

R 2”

|

380

|

340

|

200

|

110

|

4 X M12

|

60

|

10/30

|

1

|