Products

- Self-cleaning filter

- Automatic backwash filter

- Candle type filter

- Metal Sintered Backwash Filter

- Scraper Filter

- Bag filter

- Tubular type backwash filter

- Media Filter

- Cartridge Filter

- Large flow cartridge filter

- Gas Filtration and Purification

- Natural Gas Filtration and Separation

- Static mixer serial

- Filter element

Contact Us

-

0510-82621388

0510-82621388

-

0510-83782353

0510-83782353

-

No. 15, Furong Industrial Park, Xishan Economic Technology Development Zone, Wuxi

No. 15, Furong Industrial Park, Xishan Economic Technology Development Zone, Wuxi

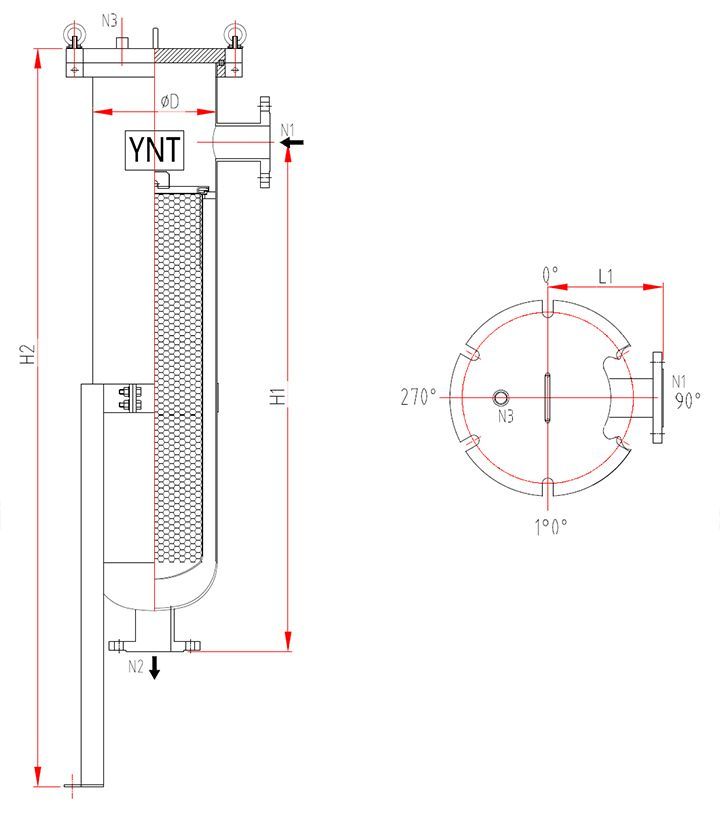

INOCO SGD-B series standard side-in type bag filter including all components are all standardized. Filter can be manufactured by line production or pressure vessel GB150. Side-in single bag filter adopts standard lug bolt to fix, connection way is standard DN50 and DN 80 flange. 4 type normal size for filter bags: size 1, size 2, size 3, size

- Product Overview

- Drawings and Data

- applied Range

- Product Configuration

INOCO SGD-S1 series standard side-in type bag filter feature

Choose appropriate bags according to flow rate

Quick open eyebolt, convenient and fast opening and closing.

Sanitary polishing can meet customer demands.

Installation size can be quickly adjusted according to the request of site

Standard bag type interface, multiple installation forms

Design, manufacture, inspection and acceptance refer to HG21637-91,GB150-2011.

Flange standard:HG GB SH HGJ JB ANSI JIS.

Connection type: thread, hoop ,flange.

Inlet& outlet size: 1-1/2”.

Drain size: 1/4”.

Filter bag model:1# 2#,3#,4#.

Filtration accuracy:0.5um-800um.

Design pressure: 1.6Mpa.

Design temperature:120℃.

Surface treatment: sand blasting, polishing, sanitary polishing

Shell material:20#、304、316L、2205、2507.

Sealing gasket: silica, NBR, PTFE

Filter bag materials: polyester, PP, PA, PTFE, glass fiber.

|

型号

|

Bag size |

Flow rate M3/H

|

Shell height (MM)

M3/H |

Total height (MM)

|

Shell diameter (MM)

|

Bag diameter (MM)

|

Inlet &outlet

|

|

SGD-II-1

|

1

|

20

|

500

|

720

|

Φ204

|

Φ170

|

1''-4''

|

|

SGD-II-2

|

2

|

40

|

700

|

1070

|

Φ204

|

Φ170

|

1''-4''

|

|

SGD-II-3

|

3

|

6

|

350

|

430

|

Φ114

|

Φ97

|

3/4''-2''

|

|

SGD-II-4

|

4

|

12

|

500

|

580

|

Φ114

|

Φ97

|

3/4''-2''

|

NOCO representative applications of high performance filter bags

|

Auto Industry

Pre-treatment ,electrophoresis paint, finish machine varnish filtration; Primer paint, paint loop line filter; Parts cleaning fluid ,filling mixture, lubricating, metal working fluid and filtration before pump. |

|

|

Chemical

Catalyst recovery: remove scale in the water pipe; Liquid clarification; Filter acid and alkali solvent; Filter emulsion and dispersion; Colloid in filter resin.In the fine chemical industry, removing activated carbon or catalyst is a typical example of high requirements,INOCO filter bags can meet the stringent requirements of these applications, high filtration efficiency while long service life and reliable. |

|

|

Electronic

Chip production process, electronic etching groove; Actinic polishing, high purity water filter cartridge as a pre-filter for multiple modes of filtration to extend its service life, cleaning is one of the key factors in achieving success in the electronics industry, because chemicals require frequent filtration of extremely low particle content, INOCO's filter bags demonstrate the required efficiency and consistency. |

|

|

Food and beverage

Beer, wine and whisky essence filtered; Remove particles from cooking oil; Remove the carbon ink from the fiber and the glue from the gelatin; Clarification of syrup concentrate and corn syrup; In addition to meeting the various and specific requirements for these applications, INOCO filter bags for starchy milk and beverages meet FDA and EEC standards for the food industry |

|

|

Metal processing

Hydraulic oil filtration; Pre-treatment filtration; Recovery of precious metals; Metal processing and filling mixtures parts cleaning machines use our filter bags to reduce residual impurities on parts. |

|

|

Petrochemical

Filter lubricating oil fuel additive; Oil recovery; Amine liquor glycol liquor filtration; Gas purification process; Distillation and fractionation processes; Machine wash amine; Offshore filtration station; Drilling oil and injection. |

|

|

Paint and enamel

Remove the clumps of paint; Solvent filtration; Remove impurities formed in storage; Packaging line and mixing line filtration, monomer purification |

|

|

Pharmacy

Recovery of expensive active materials; Recovery of catalyst; Remove activated carbon; Gelatin hormone vitamin concentrator; Filtration of herbs; Remove plasma protein; Filter brine. |

|

|

Resin plastic ink and paint

Oil and polymer filtration; Dispersion polymer production; Can coating with resin plastic synthetic paper coating high purity ink-jet filter. |

|

|

Water treatment

Well water filtration; Water treatment plants; Desilting; Remove scale from water pipes; It's too early to remove sand and debris from the sea; Recovery of ion exchange resin; Remove calcium crystals; Chemicals for filtration wastewater treatment; The application of dust in the filter cooling system in the surface water filtration is mainly based on the filter element in the past, but today, the high efficiency and longevity of INOCO's high performance filter bag is a more cost-effective choice. |

Model selection

|

Mode

|

Bag size

|

Flow rate

M3/H

|

Shell height

(MM)

|

Total height

(MM)

|

Shell diameter

(MM)

|

Bag diameter

(MM)

|

Inlet &outlet

|

|

SGD-II-1

|

1

|

20

|

500

|

720

|

Φ204

|

Φ170

|

1''-4''

|

|

SGD-II-2

|

2

|

40

|

700

|

1070

|

Φ204

|

Φ170

|

1''-4''

|

|

SGD-II-3

|

3

|

6

|

350

|

430

|

Φ114

|

Φ97

|

3/4''-2''

|

|

SGD-II-4

|

4

|

12

|

500

|

580

|

Φ114

|

Φ97

|

3/4''-2''

|

系统

伊诺特正在从单一的过滤器供应商转变成为一个较强综合能力的技术服务应用商。无论您处在哪种行业,我们都能满足您的流体系统需求。专业的制造技术

伊诺特具备GB150及ASME生产证可证,可以最大化保证袋式过滤器设计与制造的可靠性与安全性。

丰富的过滤经验

伊诺特拥有近十年的过滤经验,有为25000家客户服务的经验,能够非常及时与准确的为您的工况进行选型。

严格的质量标准

伊诺特过滤器符合ISO9001质量标准,并同时通过CE认证,也可受德国莱茵TUV检验。

个性化服务

类似衬氟或者是2507材料;高于是10MPA的过滤器;等等您的一切特殊要求,伊诺特都将尽最大可能满足,而不计较数量的多少。

标准化

标准化的单袋式过滤器,所有零部件均为标准化型号,可以实现月生产2000台,同时库存至少达到100台。

快开结构

易操作、高效益的袋式过滤器,适用于高流量的应用和频繁更换滤袋的工艺,最适合批量生产工艺和安全过滤。

高性能结构

适合一切苛刻的过滤要求 从它的高性能结构至它的精细铸件,伊诺特均按最高标准进行设计与制造。

过滤器密封结构

三点式压环保证了良好的滤器与滤袋之间的密封,附带的工具令操作非常简单容易。

最合理的流体结构

侧入底出的设计确保液体可被完全排放,同时采用了正切位出口供选择。

滤袋

多种性能的滤芯供选

不含矽油刺毯

牢固的焊接结构

滤材不会掉毛散落