Products

- Self-cleaning filter

- Automatic backwash filter

- Candle type filter

- Metal Sintered Backwash Filter

- Scraper Filter

- Bag filter

- Tubular type backwash filter

- Media Filter

- Media Filter

- Cartridge Filter

- Large flow cartridge filter

- Gas Filtration and Purification

- Natural Gas Filtration and Separation

- Static mixer serial

- Filter element

Contact Us

-

0510-82621388

0510-82621388

-

0510-83782353

0510-83782353

-

No. 15, Furong Industrial Park, Xishan Economic Technology Development Zone, Wuxi

No. 15, Furong Industrial Park, Xishan Economic Technology Development Zone, Wuxi

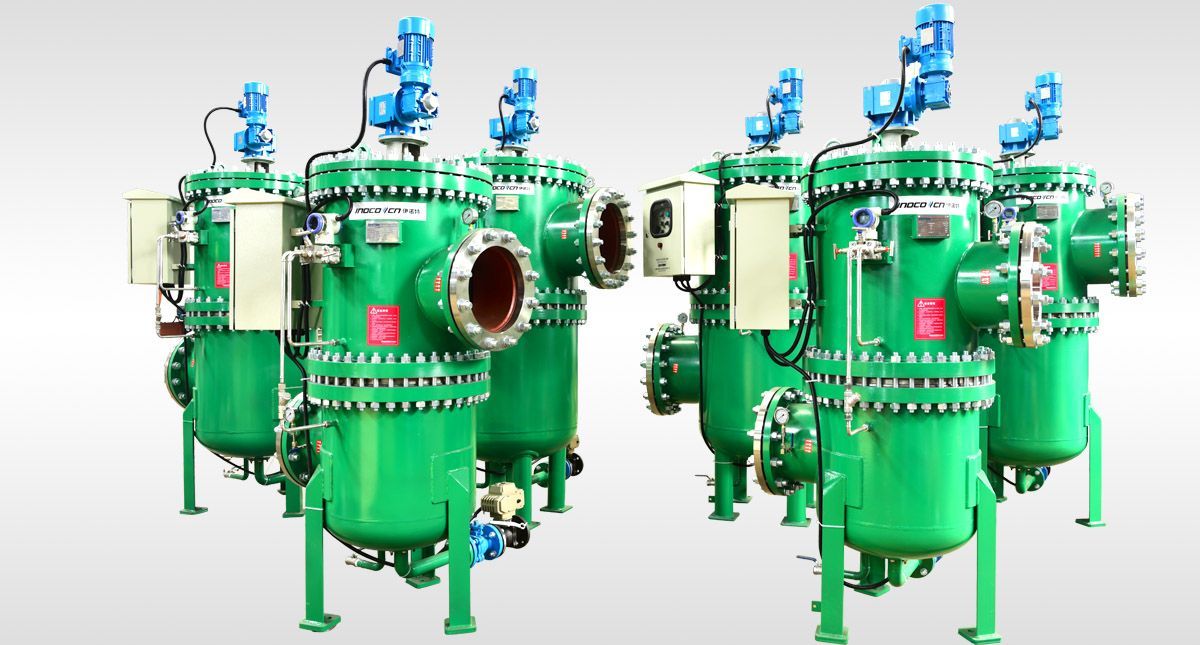

INOCO XF - F 3series automatic backwashing filter is a kind of filter which can provide a wide range of comprehensive use of industrial, it can guarantee the purity and reliability of filtrated liquid. The INOCO XF-F series suck backwash filter can be fitted with a different number of cartridges in each filter to provide a larger filtration area, which allows the filter to produce as little pressure loss as possible when used .

- Product Overview

- Drawings and Data

- applied Range

- Product Configuration

This filter provides fully automatic backwashing cleaning operations, it can continuously separate impurities from water - other liquids. The maintenance - operation of filter is very simple, even in the severe operating conditions it also can continue to keep running in a good condition.

XF - F series filter can be equipped with different amount of elements to provide maximum filtering area in each filter housing. This makes the filter to have smallest pressure loss when working.

The pressure design of filter body is usually based on the chemical pipeline filter - steel pressure vessel design standards. The filter also can adapt to the special requirements of other design criteria. Filter main body has the materials such as carbon steel, stainless steel, - duplex phase steel - etc. At the same time, we also can provide special materials such as titanium, pure nickel - etc.

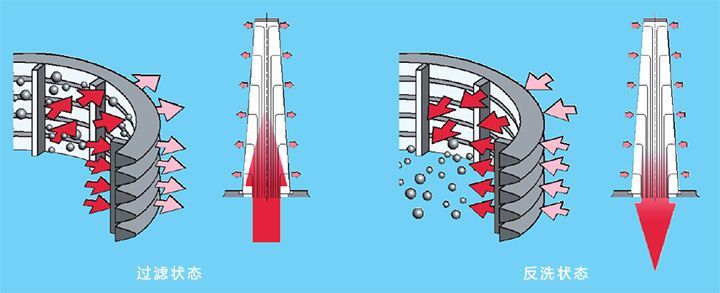

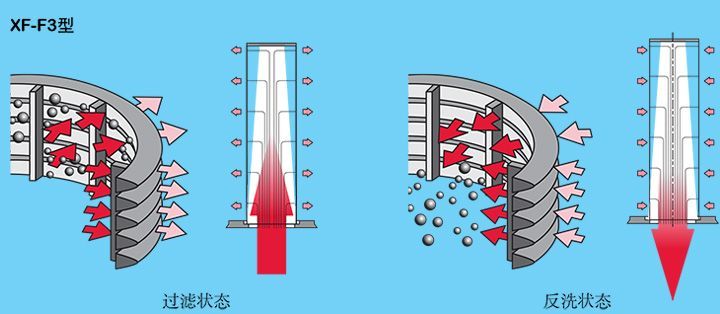

XF-F3-1 model cartridge working principle

XF-F3-2 model cartridge working principle

INOCO XF-F3 Sucking scan Backwash filter Product features

| Flow rate | 1-5000M3/H |

| Filter precision | 25-3000μm |

| Working pressure | 0-10.0Mpa |

| Valve | Motor or Pneumatic |

| Filtration standard | GB150,HG/T21637 |

| Filter element material | 304、316、Hastelloy |

| Valve material | CS、304、316、Hastelloy |

| Seal material | Buna-N、EPDM、Fluorous rubber |

Automatic backwash filter working principle

The water which needs to be filtered flows into the shell through the lower bottom of the filter and enters the lumen of the filter element through the rotary table from bottom to top and be drained out through the filter element. The filtered clean water flows out from the upper outlet of the filter. Solid impurities are trapped in the inner side of the filter element. No need of cutting off the water flow when the filter is on backwashing process. Motor drives filter wheel rotating and at the same time the drain valve was opened. Each filter element will be backwashed by the filtered clean water in turns.

The pressure difference between the water pressure in filter and the atmospheric pressure can make filtration liquid flows reversely so that the intercept impurity on inner face of the filter element can be removed. After the wheel rotates a round, backwashing process is over. Then backwashing valve closed and drive motor stops.

Model options

| flow rate sheet - filtering area | |

| accuracy(Micron) | 25 / 50 / 75 / 100 / 150 / 200 |

| flow rate(M3/H) | 8 / 12 / 23 / 33 / 47 / 58 |

| backwash media | 80 |

Above is the reference data of single cartridge - clean water medium.

Cleaning information

| drain size | DN200-DN25 |

| clean control | pressure difference - timing |

| backwash media | after filtering liquid |

| min water comsuption(L) | 10-60 |

| clean time(s) | 30 - 60(could be set) |

INOCO XF-F3 series automatic backwash filter site application